Co-Extrusion Block Rebuilding

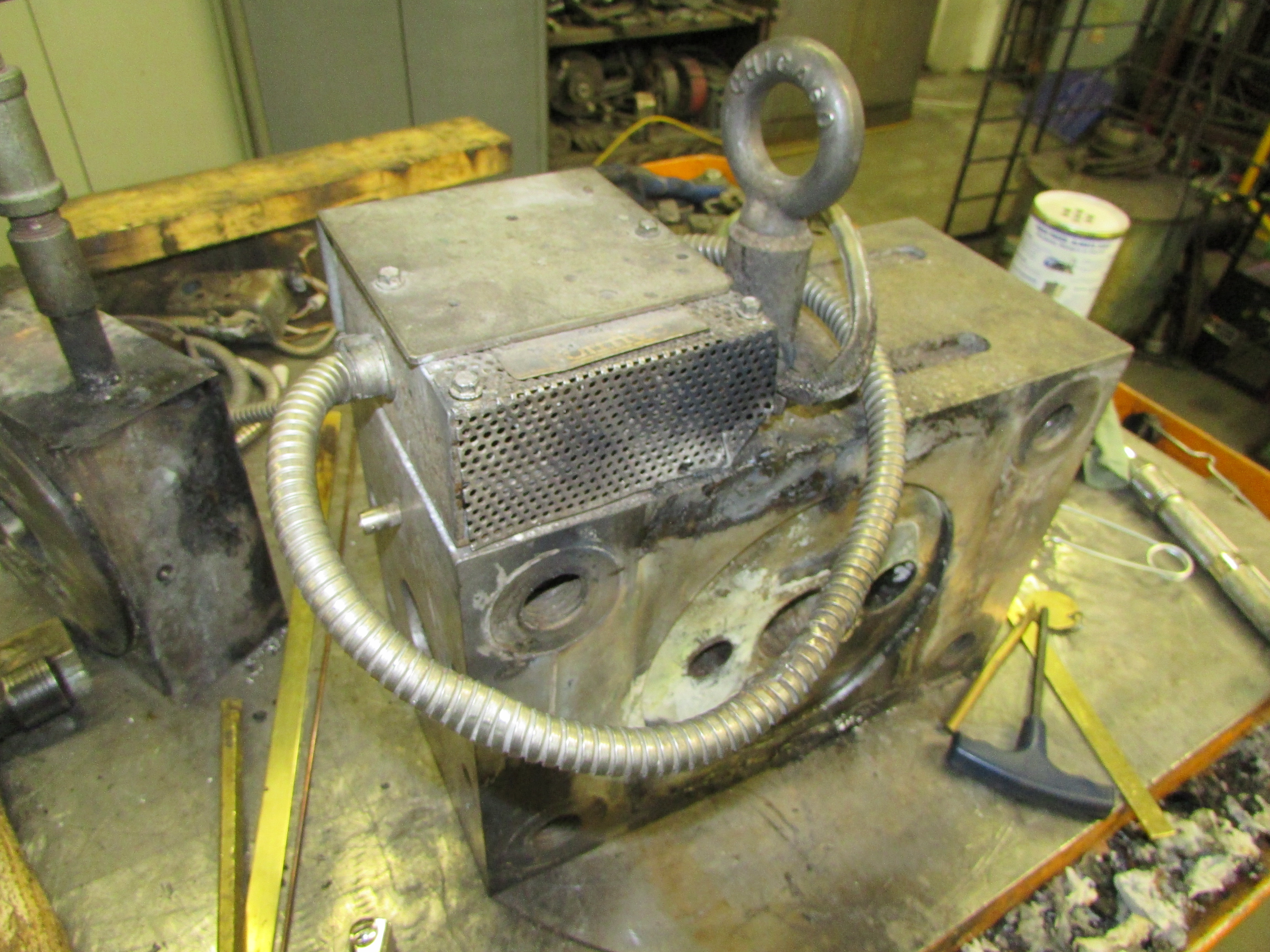

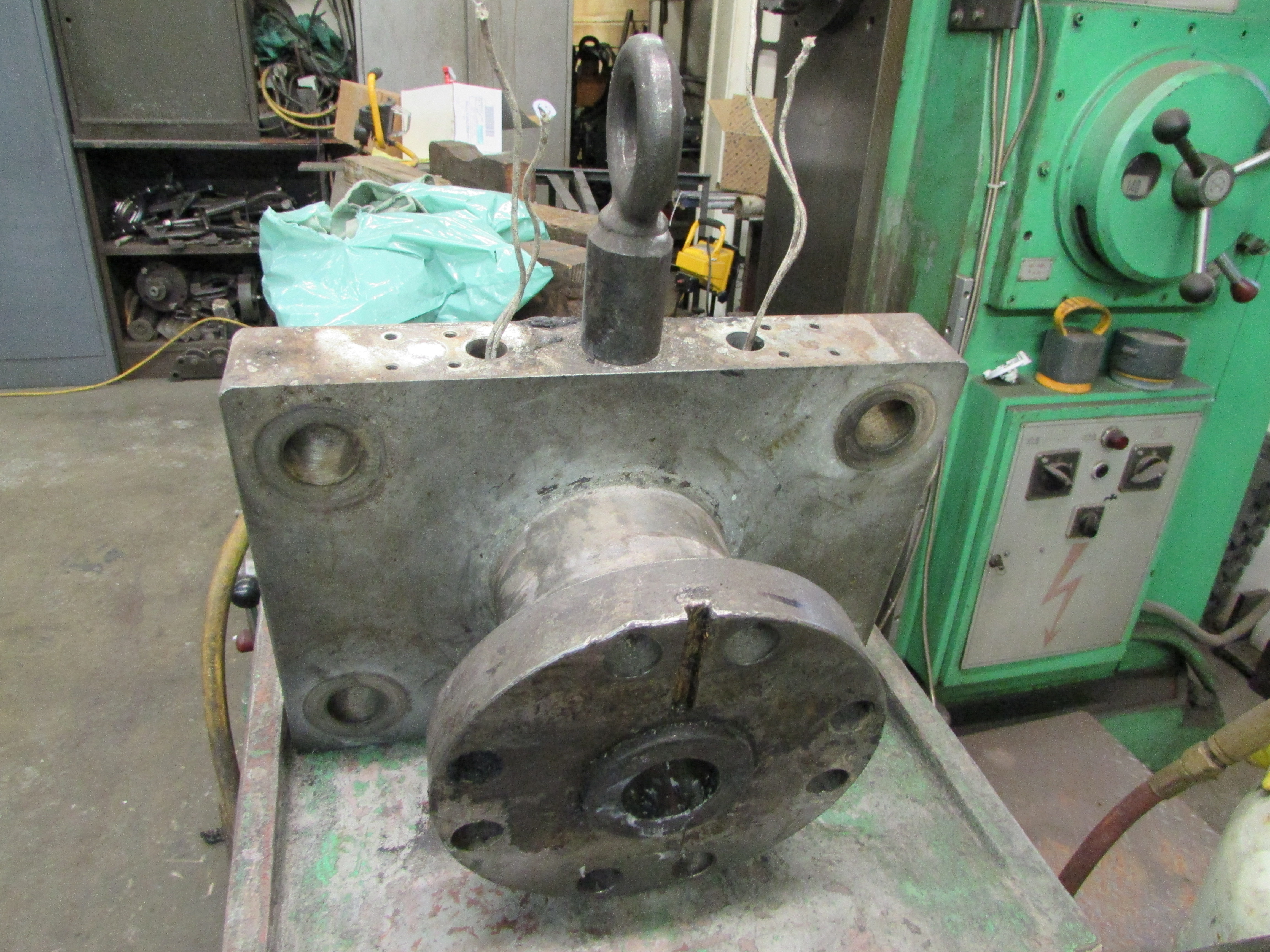

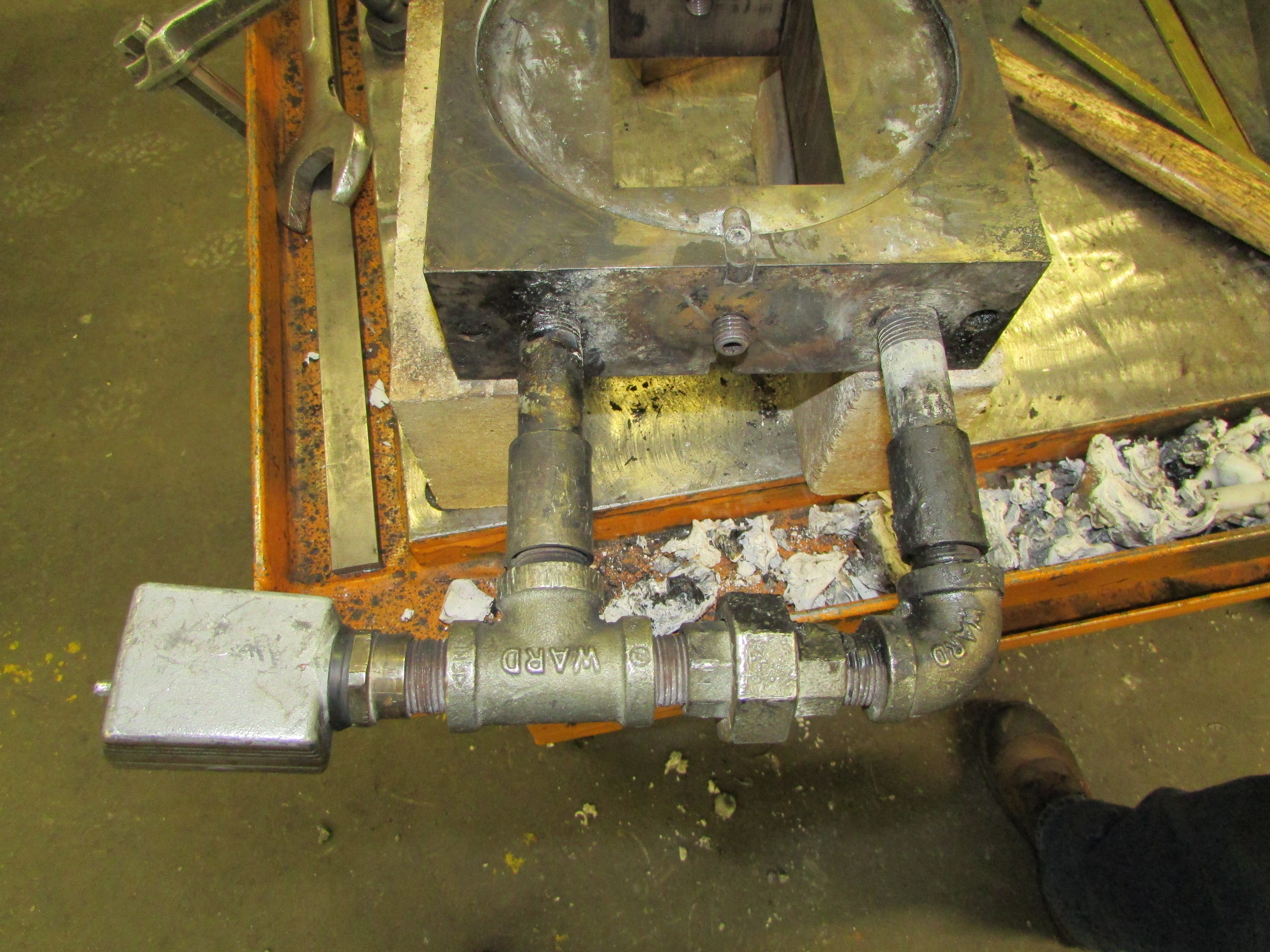

Cliff Industrial recognizes the cost effectiveness of rebuilding a piece of equipment utilizing original components to reduce the cost for the customer. Repairing and rebuilding worn or damaged machinery takes top priority because we understand that down time means production and revenue loss. Cliff Industrial specializes in Co-Extrusion Block Rebuilds. Below is a 20 year old co-extrusion block from a plastic extrusion die. The block was leaking causing performance to go downhill. Plastic extrusion manufacturers nationwide can ship us co-extrusion blocks to rebuild.

Co-extrusion block rebuilds include:

- Cleaning the plating of the die components

- Polishing of all flow surfaces

- Re-machining all mating surfaces (bosses)

- Rewiring

- New Cartridge and Band Heater Installation

- Assembly / Inspection

Our Machine Rebuilding Services

Cliff Industrial does more than just rebuild the equipment. Our skilled technicians provide solutions to accommodate to individual machines meeting custom specifications and requests, often saving valuable time and money. Cliff Industrial delivers expert welding and fuse hardfacing services designed to refurbish and reinforce the metal components used in a variety of industries. These solutions extend the useful life of these components, making them more resistant to wear, corrosion, abrasion and heat.

Quick Turn Around Time

Cliff Industrial prides ourselves on a quick turn around time. Contact us with your co-extrusion block repair details before shipping and we can turn your material around in a minimum of two weeks upon arrival. Get a free estimate today!

SM